It is widely used in mining, ferrous metal, non ferrous metal, rare metal and non-metallic concentrate and tailing discharge also environment protection sewage sludge and waste acid treatment, etc.

It is widely used in mining, ferrous metal, non ferrous metal, rare metal and non-metallic concentrate and tailing discharge also environment protection sewage sludge and waste acid treatment, etc.

Feature

Low energy consumption and running cost(low vacuum loss), low moisture content of the filter cake, and low solid content rate of the filter liquid.Can be discharged and used again and again.

High automatically, compact structure with low space, easy installation and maintenance.

Parameter

|

Model |

Filter plate / ring |

Number of filter discs / block |

Installed power/KW |

Operating power/KW |

Dimensions |

|

DF-1 |

1 |

12 |

3.5 |

2 |

1.6×1.4×1.5 |

|

DF-4 |

2 |

24 |

7 |

3 |

2.4×2.5×2.1 |

|

DF-6 |

3 |

36 |

7 |

6 |

2.4×2.5×2.9 |

|

DF-9 |

3 |

36 |

9 |

7 |

2.7×2.9×2.5 |

|

DF-12 |

4 |

48 |

11 |

7.5 |

3.0×2.9×2.5 |

|

DF-15 |

5 |

60 |

11.5 |

8 |

3.3×3.0×2.5 |

|

DF-21 |

7 |

84 |

13.5 |

9 |

4.6×3.0×2.6 |

|

DF-24 |

8 |

96 |

16.5 |

10.5 |

4.9×3.0×2.6 |

|

DF-27 |

9 |

108 |

17 |

11 |

5.2×3.0×2.6 |

|

DF-30 |

10 |

120 |

17.5 |

11.5 |

5.5×3.0×2.6 |

|

DF-36 |

12 |

144 |

23 |

16 |

6.6×3.0×2.6 |

|

DF-45 |

15 |

180 |

25 |

19 |

7.5×3.0×2.6 |

|

DF-60 |

15 |

180 |

33 |

22 |

7.5×3.5×3.0 |

|

DF-80 |

20 |

240 |

40 |

24 |

9.0×3.3×3.0 |

|

DF-100 |

20 |

240 |

53 |

35 |

11×3.6×3.3 |

|

DF-120 |

24 |

288 |

60 |

40 |

12.2×3.6×3.3 |

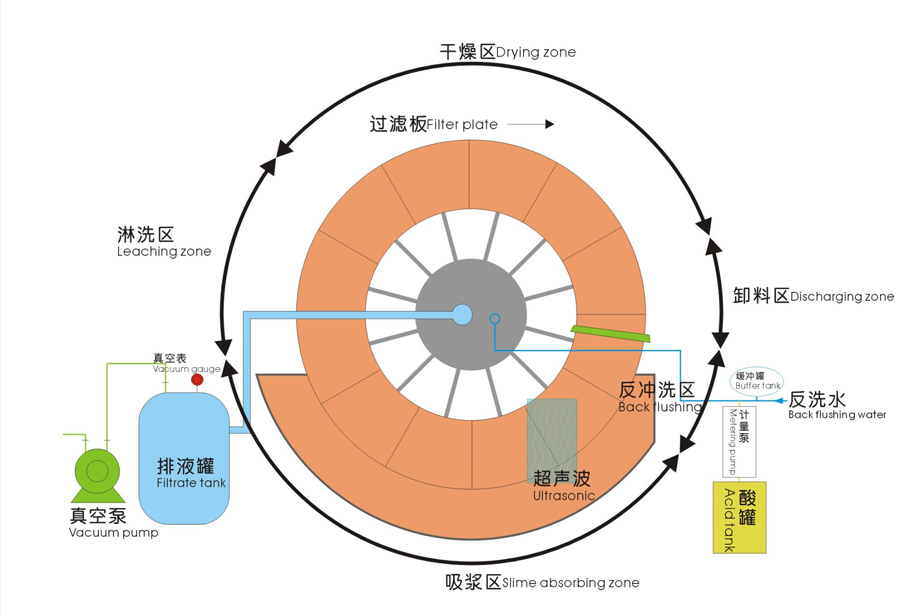

Working principle

Filter cake formed in the surface of the filter plate immersed in the slurry chute under the vacuum negative pressure via filter plate capillary adsorption. The filter liquid goes to the discharge tank through the filter plate inner pipe and discharged. The rotor drives the filter plate and the filter cake which was attached in the filter plate to dry area. The filter cake dehydrate under the vacuum environment. After filter cake get dry, the rotor rotated to the discharge area(no vacuum) and discharge by the ceramic scraper. The filter plate runs to the back flushing area after discharged, industrial water or compressed air comes to the ceramic plate chamber under the effect of the back flushing pipe and clean the ceramic plate inner hole from inner to outer. After a period of working, the ceramic plate will be cleaned by the ultrasonic with low concentration acid to ensure the high efficient use of the filter plate.

Major parts

1. Clamp off valve

2. Ceramic dispenser

3. Ceramic filter plate

4. Ultrasonic vibrator box

5. Ultrasonic power

6. Ceramic scraper

Application of the scene

Currently has been widely used in mining, ferrous metals, nonferrous metals, rare metals, non-metallic ores and tailings dewatering, and environmental protection sewage sludge waste acid treatment, etc.

Leave a Message

If you are interested in any product, please contact us. We will introduce our products to you in more detail